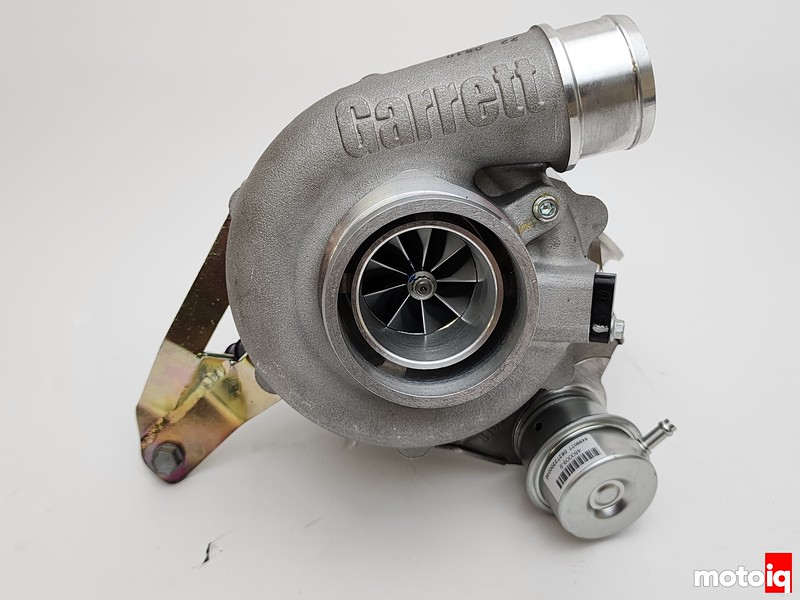

The G25-550 turbo has a ball-bearing center section in a floating cartridge. The ball bearings reduce friction and speed spool and response time by about 15% or more. The floating cartridge gives vibration damping and helps with long-term durability. The center section is water-cooled to reduce the chance of oil-coking failures.

To keep things tight and simple, since we are planning to run a fairly low boost level, we decided to run an internal wastegate. Compared to older turbos Garret’s current internal wastegate housings are designed to have much better flow and less wastegate discharge impediment.

Garrett’s new exhaust housings introduce wastegate flow as a tangent instead of perpendicular and there is plenty of room in the housing where the turbine and wastegate flows can blend with minimal turbulence for more overall flow and less backpressure.

For a moderate-power turbo system, it is often better to have low-volume, short runners in the exhaust manifold to transfer as much energy to the turbine as possible for fast spool, in this case, fast spooling is better than ultimate volumetric efficiency. With this in mind, we felt modifying the stock exhaust manifold would be the best choice – better than designing a tuned header.

4 comments

So cool to see modern tech being utilized for performance, not emissions/mpg/etc.

Looks like the build got noticed over on Jalopnik, though they gave MotoIQ zero credit:

https://jalopnik.com/nissan-sentra-det-sema-concept-could-preview-new-se-r-1850967668

Par for the course for us!

Motortrend did mention MotoIQ in their article: https://www.motortrend.com/events/nissan-sentra-det-concept-turbo-engine-sema-2023/