We fabricated an oil drain fitting to clear all the parts like axles and point in the right direction to where we wanted to introduce the oil into the pan.

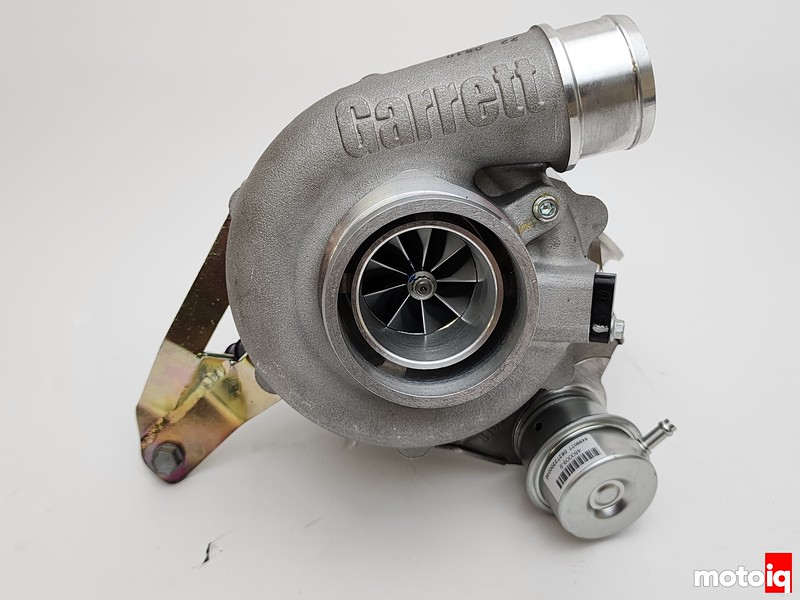

We were concerned that adding the weight of the turbo could crack the exhaust manifold with time. Zach made a sturdy bracket to mount the turbo to the OEM axle bearing support solidly. The bracket was electro-zinc plated for corrosion resistance.

Here is all of the completed fabrication of the turbo system. Everything is clean, tucked in, and sanitary with proper clearances and thermal considerations just as if the factory planned it out!

A close-up of our downpipe with the V-Band and wideband AFR sensor fittings in place.

4 comments

So cool to see modern tech being utilized for performance, not emissions/mpg/etc.

Looks like the build got noticed over on Jalopnik, though they gave MotoIQ zero credit:

https://jalopnik.com/nissan-sentra-det-sema-concept-could-preview-new-se-r-1850967668

Par for the course for us!

Motortrend did mention MotoIQ in their article: https://www.motortrend.com/events/nissan-sentra-det-concept-turbo-engine-sema-2023/