NSX DOOR FRAME:

Now I was ready to try designing my missing driver’s side door part. First, I had to get the new OEM passenger side scanned. Since the white light scanner used on Project S2000 was not available, I went to our friends at Mountune to have it scanned using their FaroArm’s Prizm Laser.

We enlisted the same service to scan the NSX’s block as part of the development of a new dry sump oiling system for the car, which we will cover in a future article.

The 3D scan creates what is known as a ‘point cloud’, consisting of millions of little dots in space.

The next step is to turn the raw point cloud into a ‘mesh body’. This converts the millions of points into a ‘mesh’ of little triangles. This is necessary to work with and modify the model.

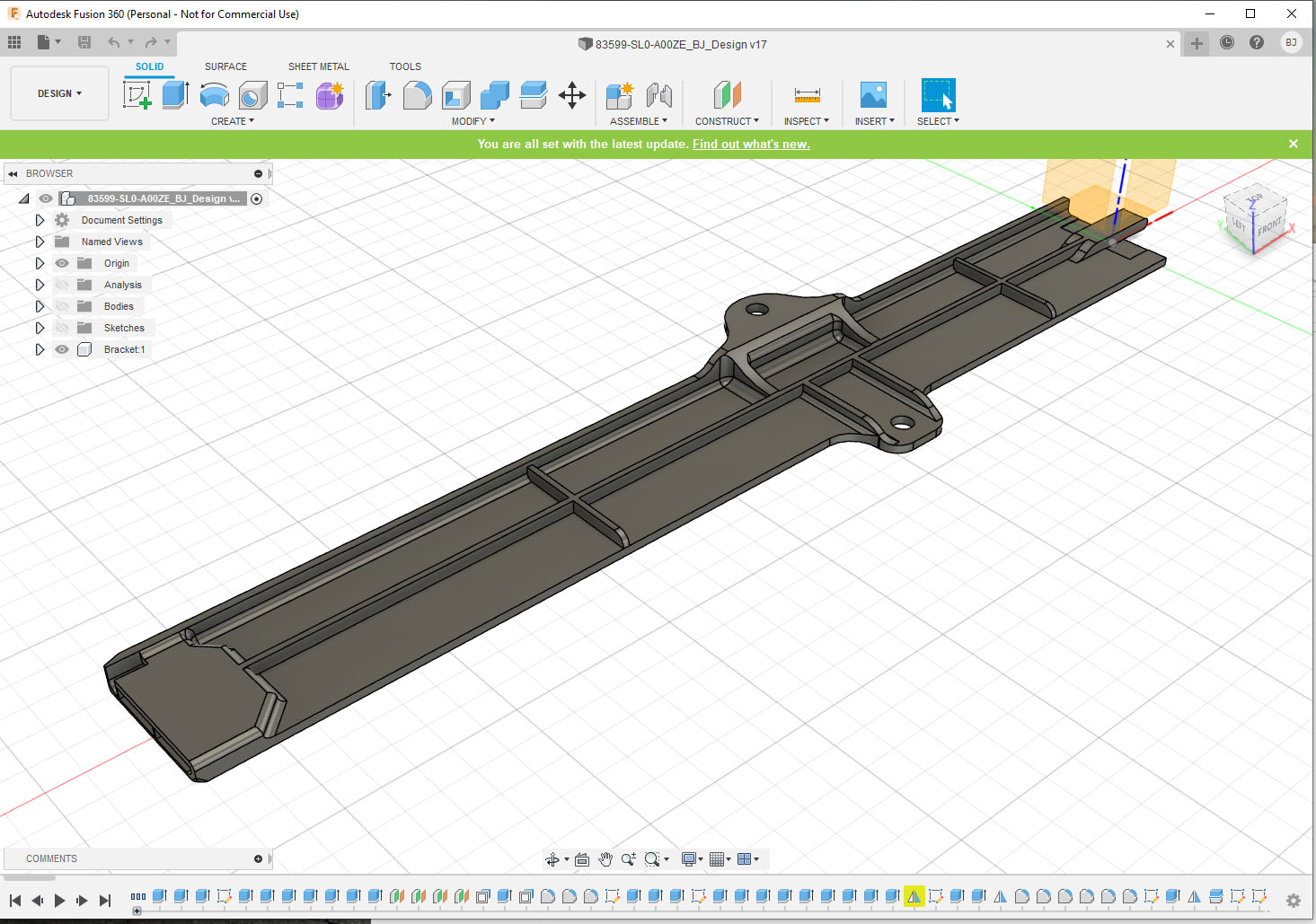

Another way to replicate a part is to use the point cloud or mesh as a template and draw a new part from scratch. This is what I did for this door frame piece. Simple sketches of the shape and size and location of the mounting holes are the foundation of making the part.

From there, each shape is extruded to the thickness of the part.

This completed design was made in 2-pieces in order to fit on the CR-10 printer’s 300×300 build plate. I radiused the edges and copied the OEM locking interface to connect the two pieces together.

Table of Contents:

Page 1 – Intro & Problem

Page 2 – 3D Printer

Page 3 – 3D Printer & Upgrades

Page 4 – Learning CAD & Making Designs

Page 5 – Designing NSX Door Frame

Page 6 – Printing NSX Door Frame

Page 7 – Fitting, Testing, and Redesigning NSX Door Frame

7 comments

So what type of material did you use for the final print

I tested a bunch of different materials, different brands, and countless print settings of each. I ended up with one of the PETG filaments.

Great article very informative!

What would you have done if you didn’t have friends at Mountune to use their FaroArm’s Prizm Laser?

Probably waited for my friend with a light scanner, or paid for one of the many places that do laser or light scanning. Or do more research looking into affordable scanning solutions.

Nice article!

I’ve been 3D printing parts for my cars for a few years now and one thing I’ve found is that ribs and walls can be made relatively stronger and stiffer for a given mass just by making them thicker but with a low infill percentage.

Obviously there are limitations with package and if you need another part of the print to have higher infill, but it can be helpful.

I have been playing with an ender 3 v2 for various projects lately and what you can do with these is really impressive. I built an enclosure for it and various upgrade parts. Still playing with PLA+, but i have some PETG to use for automotive stuff.

If you have not, remember to tape the +5V pin of the USB cable from your pi to the printer, as the printer will draw voltage from there if you cut its power. And when it tries to power 24v fans with that little 5V pin, it may burn some stuff. The 5V pin is the rightmost pin when you look at the port, placing the filled part toward the ground.

Now after going through all the R & D, do you plan to sell these pieces? Would it worth your time factoring in time and material cost?