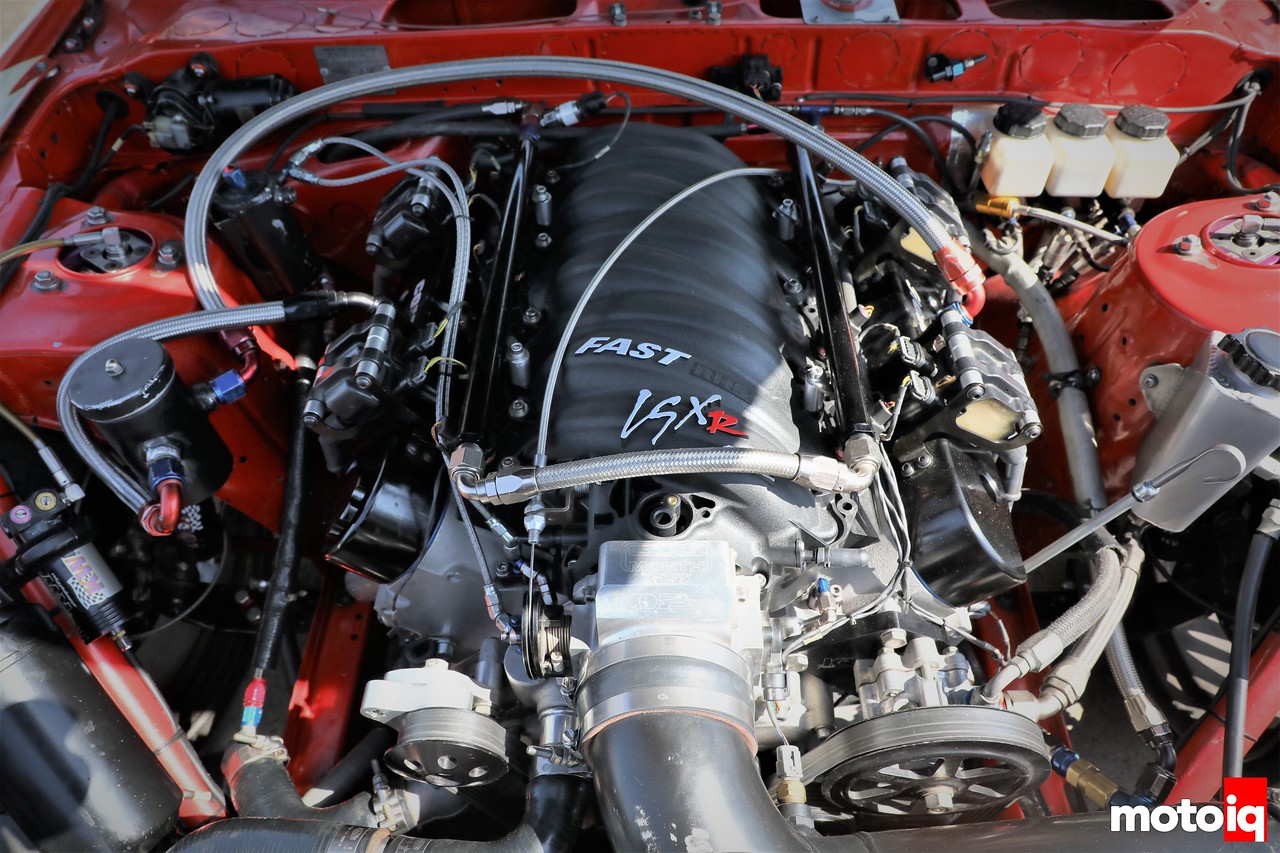

In the last edition of our engine build, restoring the engine for Dai Yoshihara’s Team Falken S13 we worked on the bottom end fortifying it with parts from JE Pistons, King Bearings, and K1 Technologies. This time around we will be completing the assembly of the engine by installing the cylinder heads and putting everything together properly.

When the old engine let go, when the connecting rod broke, the piston went to the top of the bore and smashed the valves for that cylinder. Pieces of the piston also when through the manifold and the small chunks of metal damaged the valves and valve seats in a few of the other cylinders as well. This meant that we had to replace the valves for sure and since we were on a budget, try to repair the head as well. We replaced the valves with Manley Performance Severe Duty parts.

The Manley valves are made of their NK-844 alloy on the intake and XH-428 alloy on the exhaust side, Manley’s materials give a big advantage in tensile strength at high temperatures. The valves also feature hard tips and hard-chromed stems for long life. To aid flow the valves stems are reduced in diameter near the head and are swirl polished.

To match our Comp Cam easy on the valvetrain drift specific roller cam, we specified their dual valve springs as well. To help with fatigue strength and to reduce operating temperature we WPC treated them before installation.

We used Comp Cams recommended installation kit with came with titanium retainers, machined keepers, innerspring seats and valve seals.

Although many engine builders consider shaft rockers and overkill on drift engines, we consider them to be mandatory. especially for higher-powered pro-level engines. Drift engines with their violent changes in engine rpm and banging off the rev limiter are super hard on the valvetrains and we have seen rockers get spit off the valve tips many times. When this happens the rocker slams into the retainer and knocks the keepers out causing the valve to drop destroying the engine. With shaft rockers, the rockers cannot get spit off because they are pivoting on a fixed shaft instead of a trunnion. LS engines are also thin in the area of the intake port and sometimes a drift engine with its hammering valve motion will crack in between the rocker pedestal and the intake port. This is even worse with a head like ours that has been ported. Shaft rockers spread the load out over a wider area and pretty much stop the cracking.

7 comments

Hard to believe this build is rather ‘old school’ in the LS world. Amazing that such a simple (but well designed) engine has been continuously improved by the aftermarket for 20 years now. Great photos too!

It’s a simple but overbuilt build where durability is more important than power output.

Is there anything Howard CAN’T do?

How did this engine do in the car in practical use this season? Grid life Midwest was a long, long time ago.

It’s a demo car, not a competition car. Its last outing was during SEMA Show.

What’s that got to do with anything? Just curious if it did all the things you had set out for it to do. Ran well, didn’t blow up etc.

Of course, it ran well.