Howard puts a thin layer of assembly lube on each valve stem.

Howard slides the valve into place, then compresses the spring with this spring compressor. With the springs compressed the keepers are put into place.

The head with the valves and the springs properly assembled await the next step.

Next, the shaft rocker geometry must be set. This gauge that comes with the rockers is used to make sure the rocker shaft is perpendicular to the valve stem.

The gage is set on the valve stem and it must touch the shaft rocker without any gap. If there is a gap the distance is closed up with shims under the rocker pedestals to close it up. For milder cams with a lift less than 0.750″ like ours a 0.020″ feeler gauge is stuck between the valve tip and the gauge and the gap is adjusted and eliminated accordingly.

Now the rocker shafts can be installed.

7 comments

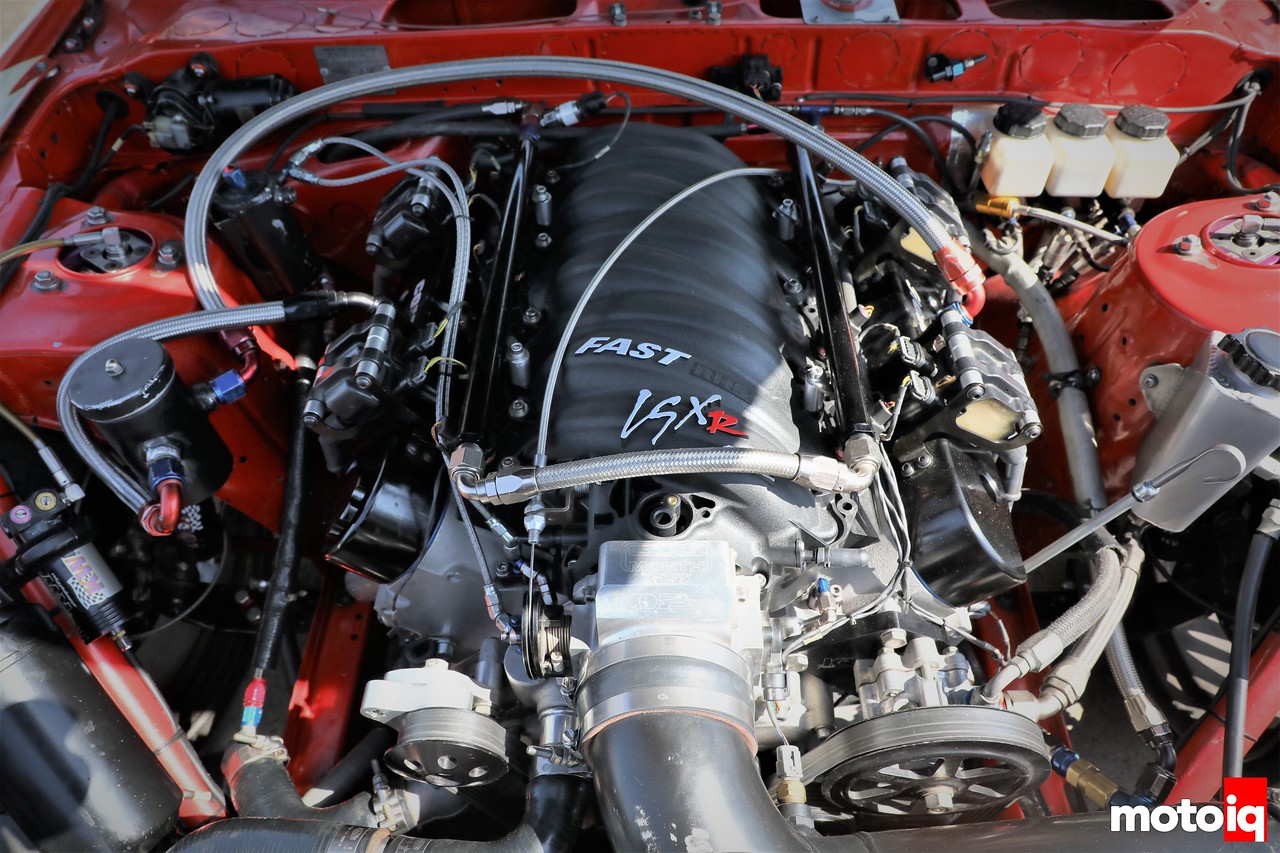

Hard to believe this build is rather ‘old school’ in the LS world. Amazing that such a simple (but well designed) engine has been continuously improved by the aftermarket for 20 years now. Great photos too!

It’s a simple but overbuilt build where durability is more important than power output.

Is there anything Howard CAN’T do?

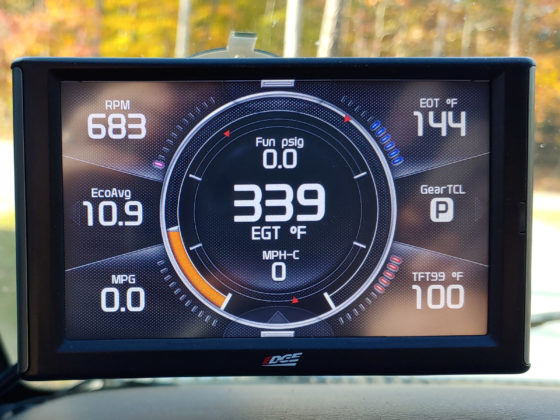

How did this engine do in the car in practical use this season? Grid life Midwest was a long, long time ago.

It’s a demo car, not a competition car. Its last outing was during SEMA Show.

What’s that got to do with anything? Just curious if it did all the things you had set out for it to do. Ran well, didn’t blow up etc.

Of course, it ran well.