The valve cover vent baffles are installed on the Comp Cams valve covers. Good vent baffles and cover venting help prevent excessive oil consumption caused by excessive crankcase pressure and reduce oil getting blown out of the valve cover vents. Shaft rockers take up more room than the stock rockers so many valve covers won’t fit over them. The Comp Cams valve covers do.

The Comp Cams valve covers have provisions for coil brackets. These brackets get the coils off the valve cover and allow them to run cooler. We have had LS coils fail from excessive heat exposure before and this will help the coils run cooler.

Here are the coils bolted in place. We used FAST XR high energy coils for a stronger spark.

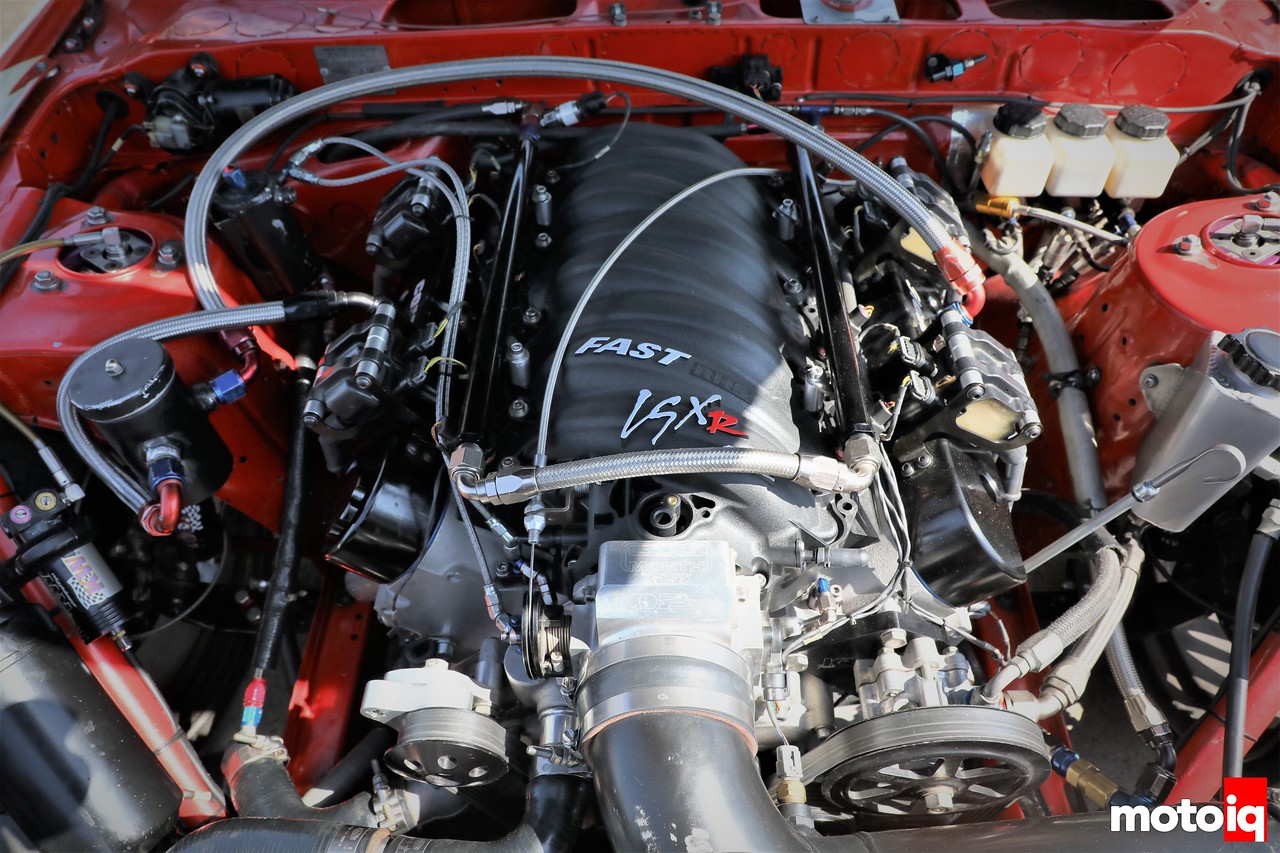

Next, we bolted down our FAST race runner intake manifold.

Next, we installed the FAST 102mm throttle body from the old engine. er

We used FAST fuel rails for the existing RC engineering injectors.

One important step that a lot of LS swappers neglect is the cylinder head vent lines. Not having proper air bleeding is a cause of overheating in many an LS swap that we have seen. We were sure to use the vents!

7 comments

Hard to believe this build is rather ‘old school’ in the LS world. Amazing that such a simple (but well designed) engine has been continuously improved by the aftermarket for 20 years now. Great photos too!

It’s a simple but overbuilt build where durability is more important than power output.

Is there anything Howard CAN’T do?

How did this engine do in the car in practical use this season? Grid life Midwest was a long, long time ago.

It’s a demo car, not a competition car. Its last outing was during SEMA Show.

What’s that got to do with anything? Just curious if it did all the things you had set out for it to do. Ran well, didn’t blow up etc.

Of course, it ran well.