Our King XP Bearings are set into the block saddles and given a coat of engine oil on there crank side. It is important to keep the block side dry.

The cap sides of the studs are lubricated with ARP assembly lube. This is critical for getting the torque readings correct.

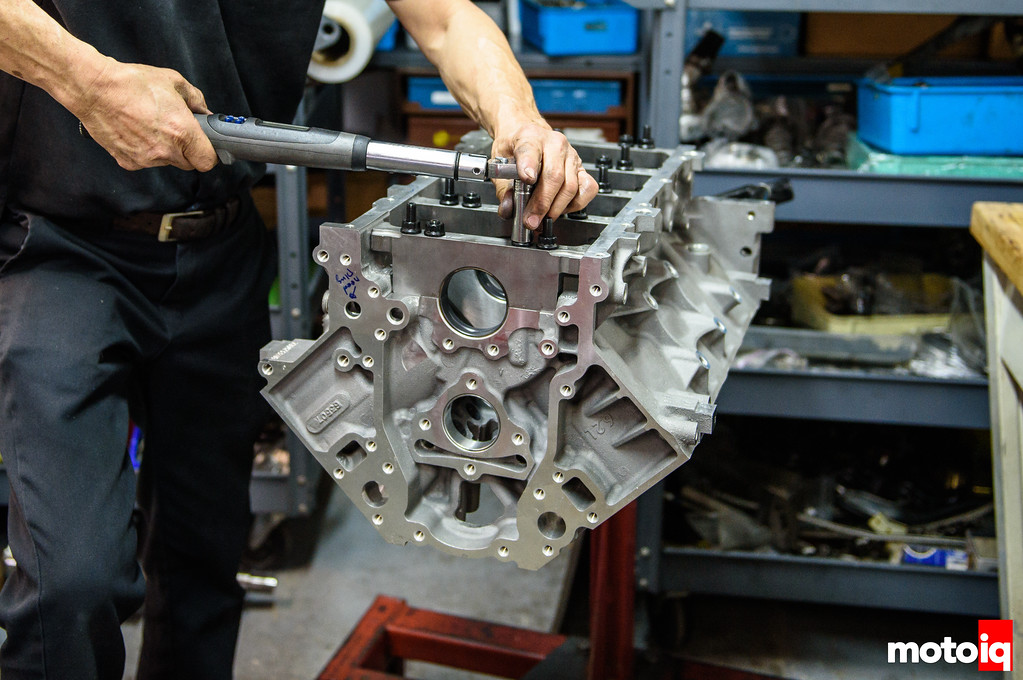

Our ARP studs are screwed into the block. The studs are much stronger than the stock bolts and can be re-torqued many times if need be. Studs also don’t wear out the threads in the block.

The studs are tightened into the block.

The nuts for the ARP studs are lubricated with ARP assembly lube under the head. This is also a critical lubrication point for accurate torque readings.

All of the studs are now tight in the block and lubricated up. Now its time to temporarily install the main caps.

5 comments

I don’t have much in the way of comments but I’m really interested to see how this turns out – from the parts selection and goals, this looks like a really really useful build spec for a lot of purposes.

With the relatively big cam (I certainly like the idea Comp has there, if it works as expected) but highish compression, what are you anticipating for octane requirements, or are you just accepting as a given it’ll be E85/race gas fed?

I think this engine will be great for drift, road race, and any long-duration type use. It will need something like E85 or a race fuel like VP110.

I was thinking that with the compression tuned down a bit (or just fed E85) it might make a really fun “hot street” combination as well, at least for those of us with tolerance for some compromises on drivability.

Yeah E85 only it would be! The engine is very driveable, it just has a rocking idle!

Hello can you give me a quote for the ls3 complete engine you built for the falken s13 drift car.thank you