Howard fits the King XP bearings into the main cap saddles. We are using King’s new pMaxkote nanoparticle coated bearings. We have had good results with this new coating in race engines that we have serviced, with amazingly little bearing wear, even in severe use. After the bearings are in place, Howard gives them a light coating of motor oil on the crank side while leaving the block side bone dry.

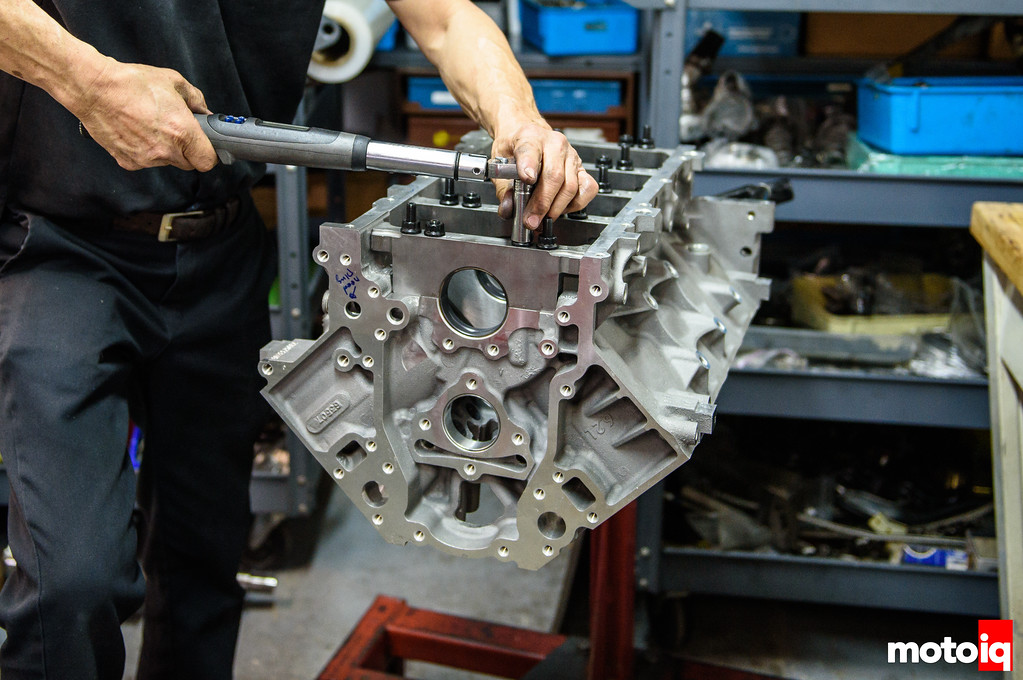

The block’s main caps are installed and torqued down so the bores can be measured so the journal oil clearances can be confirmed and adjusted if needed. To measure the clearance the caps must be fully tightened to operating torque as things distort and the bore size changes when things are fully tight.

Like the crank, Howard measures each main bearing journal bore in three places across the bearing and around the bore to detect any taper or out of roundness that may need to be corrected by aligning boring. By subtracting the two bore diameters, the main bearing clearance is determined. If the clearance is too tight or too loose, it can be adjusted by changing the bearing shells to one of King’s three sizes to get the clearances perfect. Select-fit bearings are exactly how the OEM’s control clearances as well. In this case, we were able to use standard King bearings.

After giving the Eagle crank a final fine cleaning, Howard blows it off before installing. The journals are also given a light coat of oil. At the MotoIQ garage, we always do additional cleaning before assembly.

Howard applies motor oil to the main bearings and drops the Eagle 4″ stroker crank in place. The Eagle crank has their optional ESP armor treatment which is very much like WPC. This provides an ultra-smooth surface with less friction, less windage loss, longer life and crack resistance. Since the crank came ESP Armor treated we did not WPC treat it as that would be redundant.

5 comments

I don’t have much in the way of comments but I’m really interested to see how this turns out – from the parts selection and goals, this looks like a really really useful build spec for a lot of purposes.

With the relatively big cam (I certainly like the idea Comp has there, if it works as expected) but highish compression, what are you anticipating for octane requirements, or are you just accepting as a given it’ll be E85/race gas fed?

I think this engine will be great for drift, road race, and any long-duration type use. It will need something like E85 or a race fuel like VP110.

I was thinking that with the compression tuned down a bit (or just fed E85) it might make a really fun “hot street” combination as well, at least for those of us with tolerance for some compromises on drivability.

Yeah E85 only it would be! The engine is very driveable, it just has a rocking idle!

Hello can you give me a quote for the ls3 complete engine you built for the falken s13 drift car.thank you