In our last segment, we gave you a look at the 415 cubic inch or 6.8 liter Chevy LS drift motor we are building for Falken Tires ex Yoshihara championship-winning Nissan S13. Currently, the car is making its rounds as a demo car for Falken. After destroying an off the shelf crate motor that was powering the car for non competition demos, Falken Tires needed a new motor for the car and we proposed that MotoIQ build them one that would be similar in performance to the engine that won the 2011 championship which would also be more reliable than the lower cost crate motors that the car had been running. With some improvements in technology since 2011, we think we can build a lower cost LS that will perform better than the engines Dai was running in 2009-2011!

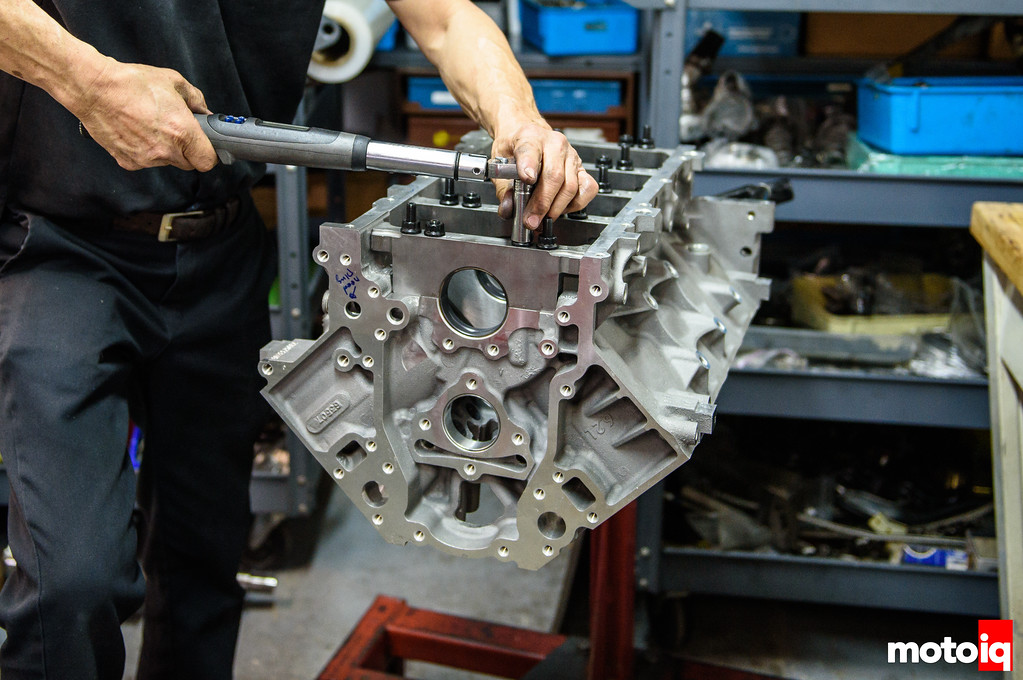

Since the old engine block was destroyed by a broken rod, we had gotten a new LS3 block from Scoggin Dicky Chevrolet, a Chevy dealer with a big online performance parts business. They had the best prices beating other dealers wholesale prices. After measuring the bores to double-check the piston to wall clearance and giving each bore a few strokes with a plateau finishing flex hone, we sent the block out to WPC Treatment to get there super finishing metal finish done on the bores. We have found that this can give the bores up to a 100% longer service life.

Here Howard is setting the compression ring end gap. At the MotoIQ Garage, we normally get our rings slightly oversize so we can set the gaps to exactly what we want. To set the gap Howard uses an old piston to push the ring down the bore about an inch so he can measure the gap with a feeler gauge.

Howard then grinds the ends of the rings a little bit at a time to get the precise ring gap on all 8 cylinders. Getting the ring gap perfect is a good way to create the optimal ring seal and thus make good power. It also assures that as the rings expand with heat, you won’t have the ends of the ring butt together. This is not good for the rings or bore.

Once the ring gap is set, Howard deburrs the sharp edges of the ring ends with an oil stone to eliminate the chance that a sharp edge could scratch the cylinder walls in operation. After the ring gaps were set, the rings were sent out to be WPC treated. This will help their service life and help prevent fretting and sticking of the rings in the ring grooves, even in our high compression engine.

We had already sent the crank, rods, and pistons out to be balanced. Because machining is so good nowadays, modern quality performance parts usually don’t have to be balanced but we send our parts out to get double checked and rebalanced if needed.

Here Howard measures the journals on our Eagle crank. Howard measures the journal in three places across each journal and in three places around the journal. This spots any taper or out of round in the part. If the crank measures properly, then the journal diameters are recorded and used to set the bearing clearances.

5 comments

I don’t have much in the way of comments but I’m really interested to see how this turns out – from the parts selection and goals, this looks like a really really useful build spec for a lot of purposes.

With the relatively big cam (I certainly like the idea Comp has there, if it works as expected) but highish compression, what are you anticipating for octane requirements, or are you just accepting as a given it’ll be E85/race gas fed?

I think this engine will be great for drift, road race, and any long-duration type use. It will need something like E85 or a race fuel like VP110.

I was thinking that with the compression tuned down a bit (or just fed E85) it might make a really fun “hot street” combination as well, at least for those of us with tolerance for some compromises on drivability.

Yeah E85 only it would be! The engine is very driveable, it just has a rocking idle!

Hello can you give me a quote for the ls3 complete engine you built for the falken s13 drift car.thank you