Check out the entire project to date!

For MotoIQ Merch and Parts Check out our Store!

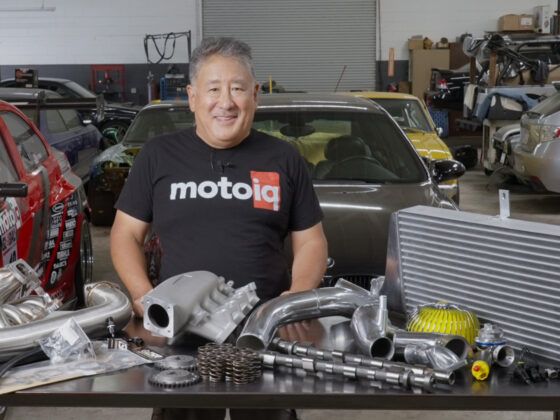

With our do-it-all all S-Chassis suspension and brakes nearly done, it is time to focus on the engine. It has been a long time since we have focused anything on the SR20 and even longer since we have done anything on a turbocharged one, but we will do some nice work here. The SR20DE and DET are very strong engines in stock form as long as you do not greatly exceed the engine’s base design limits. With a stock bottom end and careful tuning, these engines have held up to over 400 hp of boost as long as they are not overheated, the engine oil supply is maintained and the tune is careful with no detonation.

Since our car is being built purely for demanding track use and drifting and since drifting requires good response and bottom-end torque, we are not going to try to obtain the most stock bottom-end bolt-on power possible but something that can be reliable for long periods under tough conditions with a broad powerband and minimal turbo lag. Our engine is going into an RWD S13 but most of the tricks we are going to cover can also be applied to the FWD SR20DE found in the Nissan Sentra SE-R, 200SX, and Infiniti G20s.

So for reliability and thermal control reasons we are setting out power goals very modestly, at around 330 whp and 300 lb/ft of torque with minimum lag at the lowest boost possible. Our first step in achieving our goal is replacing the tiny T25 OEM turbo with something more efficient. After a lot of study, we settled on the Garrett GTX2863R. The 2863R is a small frame turbo that is a direct bolt-on replacement for the stock T25 but it packs a pretty big punch.

The GTX2863R has a 63mm high flow compressor wheel with a 47mm inducer with a trim of 56, nice and small with low inertia for fast spool. The turbine wheel is 54mm with a 47mm exducer and a trim of 76. This nice and small major diameter assembly is going to spool fast. The compressor wheel lives in a 3″ inlet ported shroud TO4B type compressor housing. The ported shroud gives more surge margin which can be important in a fast spooling turbo whose speed in spooling may exceed the engine’s ability to ingest the boost pressure at low RPM. The exhaust housing is a largish 0.86 A/R which can flow an amazing 19 lbs an hour. This will ensure low backpressure while still giving decent spooling ability.

What is really cool is that the newer GTX technology gives this tiny turbo the abilities of the much larger T4/T3 hybrid turbos that we used to experiment with back in the day, like in the 90s. The reason we are going with this turbo instead of the newest state-of-the-art G Series turbos is that there are currently no inexpensive manifolds for these turbos that use V-Band housings in the sizes we would want. We also wanted to pick a turbo that could fit on most of the common T25 flange manifolds and downpipes as well as the stock manifold. In the future, we will probably switch to a G series but right now, we wanted to show what the older but still much higher-tech turbos can do.

When looking at the compressor map, it is pretty obvious that this turbo kicks some ass. Our 330 hp goal is going to be right smack in the turbo’s highest and a bit in the second highest efficiency islands, 78 and 77 percent efficiency. This is a huge number, especially for a small-frame turbo. This means that the charge air will not be heated much and that the turbine does not have to recover as much power to drive the compressor at the boost levels we will need to target. We are only going to need 15-16 psi to make our target power. High efficiency also means less turbo lag.

A lot of long-time MotoIQ readers probably know about the exploits of the famous Disco Potato turbo or the GT2860RS and the magic it can bring to a 2 liter 4 banger. The good old Disco Potato cannot hold a candle to the GTX2863R. Here are the overlayed compressor maps of both turbos. The Disco Potato says bye-bye at 22 psi of boost while the GTX2863R can still produce useful boost to more than 28 psi. The Disco potato can flow enough air to make 350 hp albeit without much efficiency but under the same conditions, the GTX2863R can make 430 hp!

9 comments

“The stock SR20DET intercooler is a joke, it is tiny, perhaps the smallest air-to-air intercooler we have ever seen”

Challenge accepted: https://motoiq.com/project-cappuccino-a-wee-bit-o-power/3/

Ok you win! Is that an oil cooler.

A manifold to behold!

Artec in Australia can provide v band manifolds for the sr20

What we wanted was inexpensive, simple and the ability to combine with any lash up of OEM and aftermarket parts to make this a pure bolt on with no fabrication needed. We know about Artec stuff, it just doesnt meet any of those criteria.

So cool. You guys live like Gran Turismo is real life, but better.

Hey Mike!

Great information!

Question. If you were to choose between the GEN 2 GTX, 2860r or 2867r for this build, what is your pic?

Thanks! D

The one we picked

How did you guys have the turbo clocked I bought the gtx2863 r and when clocking my turbo the only position I could get it in is the outlet is facing down toward the frame rail I also have it on the same manifold