The previous engine builder used injectors that were too small then used a really high fuel pressure to force more fuel out of them. The side load put on the pintles from high fuel pressures can cause inaccurate and inconsistent response from the injectors and cause them to wear out quickly like the hammered injectors in the motor were. Now that we have proper injectors with headspace in case Rathyna wants to run E85 or Nitrous in the future, we are in a lot better shape fuel system wise.

10 comments

The LQ9 isn’t the iron block version of the LS3, they’re not even from the same LS Generation (LQ9 is Gen III and LS3 is Gen IV).

Sure the LQ9 is a Gen III and the LS3 is a Gen IV but there are not many differences between the Gen III and Gen IV engines and most parts interchange. The major differences between engine generations here are some to accommodate DOD and VVT options that the LS3 does not use anyway. Where it affects you, in this case, is a single bolt vs 3 bolt cam for the sprocket. The LQ9 has a 4″ bore with the same stroke but its iron block can easily be bored to the LS3’s 4.065, all the internal parts interchange. The heads are the square port, LS3, L92 improved square port configuration and everything interchanges. A lot of Chevy tuners like the LQ9 for an inexpensive forced induction block as the iron block is stiffer under boost. Its cheaper than the LS7 based six head bolt solutions for better head sealing under pressure.

I would highly avoid using the compcam trunion upgrades. They fail at an extreme rate.

Just check out some of these failures.

https://www.corvetteforum.com/forums/c6-tech-performance/3546465-fail-comp-cams-trunion-upgrade.html

I’ve read nothing but bad things. Ton of posts of exactly the same bearing failure. They just have a poor design.

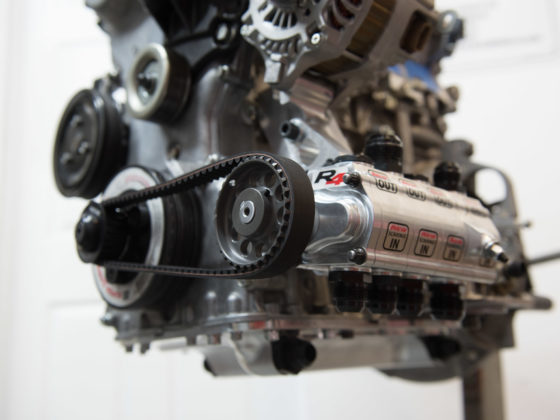

The Comp Cams Trunion has a lot more bearing area than stock. As you can see in this picture the size difference in bearing area between stock and Comp Cams. You can also see that the stock trunions were beginning to gall on this engine with a stock cam and valvetrain. Installation does require some finesse and proper use of a press. A lot of people have good luck with this kit and perhaps some of the early failures were perhaps caused by improper heat treating and installation.

I have seen many failures of stock rockers in high-level drifting which is more brutal than drag and road racing in some ways. Check out the pictures and the galling of the stock shafts.

https://photos.smugmug.com/MotoIQ/Project-Cars/Project-Pink-350z/i-PKXPZXt/0/cf264521/L/DSC_0817-L.jpg

Your info is good to know and thank you for bringing it to our attention and we will be keeping an eye on them but I don’t think we will have problems. We will report if we have issues.

Lots of recent failures of the comp kits.

https://www.corvetteforum.com/forums/c6-corvette-zr1-and-z06/3802785-failed-comp-cams-trunions.html

I would not use them. Better alternative is either straub kit or CHE precision.

https://www.corvetteforum.com/forums/c5-tech/4130290-che-trunion-upgrade.html

LS3 is not the same bore as LQ9. 4.065 Bore vs 4.00

You are completely right, our block is bored out quite a bit to 4.065 and you can go as much as 4.090 as I recall which you can’t do with the aluminum blocks. Everything does interchange between the two motors though.

Due to Rathyna’s penchant for not maintaining anything,

Lol a woman not take care of her car?!!?!?! Unheard of!

Men can do this as well… Has nothing to do with sex.

I unfortunately wasn’t really raised or taught to maintain vehicles. I have always been a driver, and the circles I associated with growing up never emphasized car maintenance. It was all about driving. Luckily I found MotoIQ and they’re teaching me a different way – it’s kind of a running joke with me at this point. I’ve gotten better…not quite good at it yet, but I at least understand the importance of vehicle maintenance and safety now 🙂

TGI for MotoIQ <3