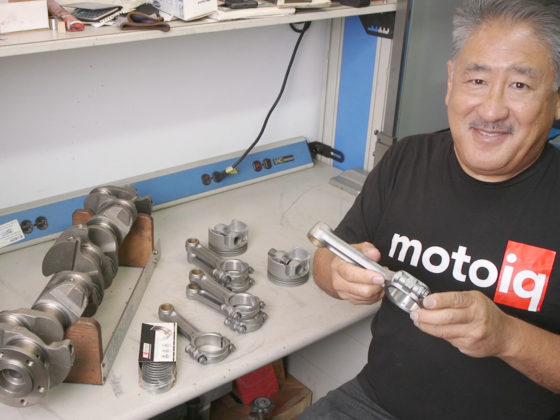

In our previous articles, we covered the build-up of our EJ257 engine collaboration with IAG Performance. Now we have been collecting a bunch of parts to make our installation go smoother and for compatibility with our new more powerful engine. As a recap, our engine is built to easily withstand more than 600 hp but we are going to run it with a responsive smallish turbo to get quick spooling hp in the mid to high 400 hp range. To support all of this we are going to cover the peripheral parts needed to put the package together. In this segment we talked about prepping the engine case, here we talked about the bottom end, the cylinder heads were discussed here, The assembly of the short block here, finally the assembly of the engine was done here.

To handle the engine’s anticipated higher flow levels, we are replacing our 2.5 in catted Cobb downpipe with a newer 3″ part. Like our old part we will be running a cat but just with bigger diameter tubing.

Here are more details about the downpipe and other bolt-on parts.

For the intake side, we will be replacing our welded-up stock TGV valves with IAG’s billet TGV deletes. These CNC machined billet parts fit perfectly and do a much cleaner job than our hacked-up previous solution!

In the last iteration of our engine’s progression, we had maxed out the stock mass airflow meter so to improve drivability and give us plenty of flow headspace, we are converting to Speed Density mass flow estimation. We are using an IAG kit to do so. We get a conversion wire sub-harness and an adaptor for a 3 bar MAP sensor as well as a different intake air temp sensor.

We are running a Cobb MAP sensor with the IAG kit.

3 comments

Love all the updates, and that its all finally coming together!

One word of caution is any pitch stop mount, from the aftermarket, seems to just perfectly resonate the factory firewall.

If you have the chance getting a good CLD layer in and as high up as possible on the firewall surrounding that immediate area in-cabin, opposite the mount will make a dramatic difference in reducing NVH. If only 50% of the firewall were covered, that is enough. e.g. 4-5sqft total. Minimal weight added, but very targeted to that part. SecondSkin, Resonix, Dynamat Extreme are all good examples of quality CLD tiles that can handle heat and not put off a strong smell.

Can’t wait to see this all come together. Best wishes for reliability and longevity. HP per dollar spent be damned lol

Any picks of install of the COBB’s Overflow Tank and Washer Reservoir filler? I am interested in that kit and install.