In our last article, we discussed the modifications needed to the bottom end on our super pump gas Honda K series engine to get it up to snuff. Now we are going to focus on the heart of an engine’s power creation, the top end with help from Drag Cartel, Supertech Performance, and Hondata.

The cylinder head is responsible for the majority of the engine’s power production as it includes the cams which directly control an engine’s volumetric efficiency, as well as the intake and exhaust ports who’s flow capacity, also has a direct effect on an engines VE. The heads combustion chamber shape and geometry not only affects VE but also the engine’s thermal efficiency and detonation tolerance which has a synergistic effect on tuning for power. This is why the engine’s top end is always so key in its ability to produce power.

Fortunately for us, the Honda K Series engine has an excellently designed cylinder head right from the factory. Excellent head or not, it doesn’t mean it can’t be improved on!

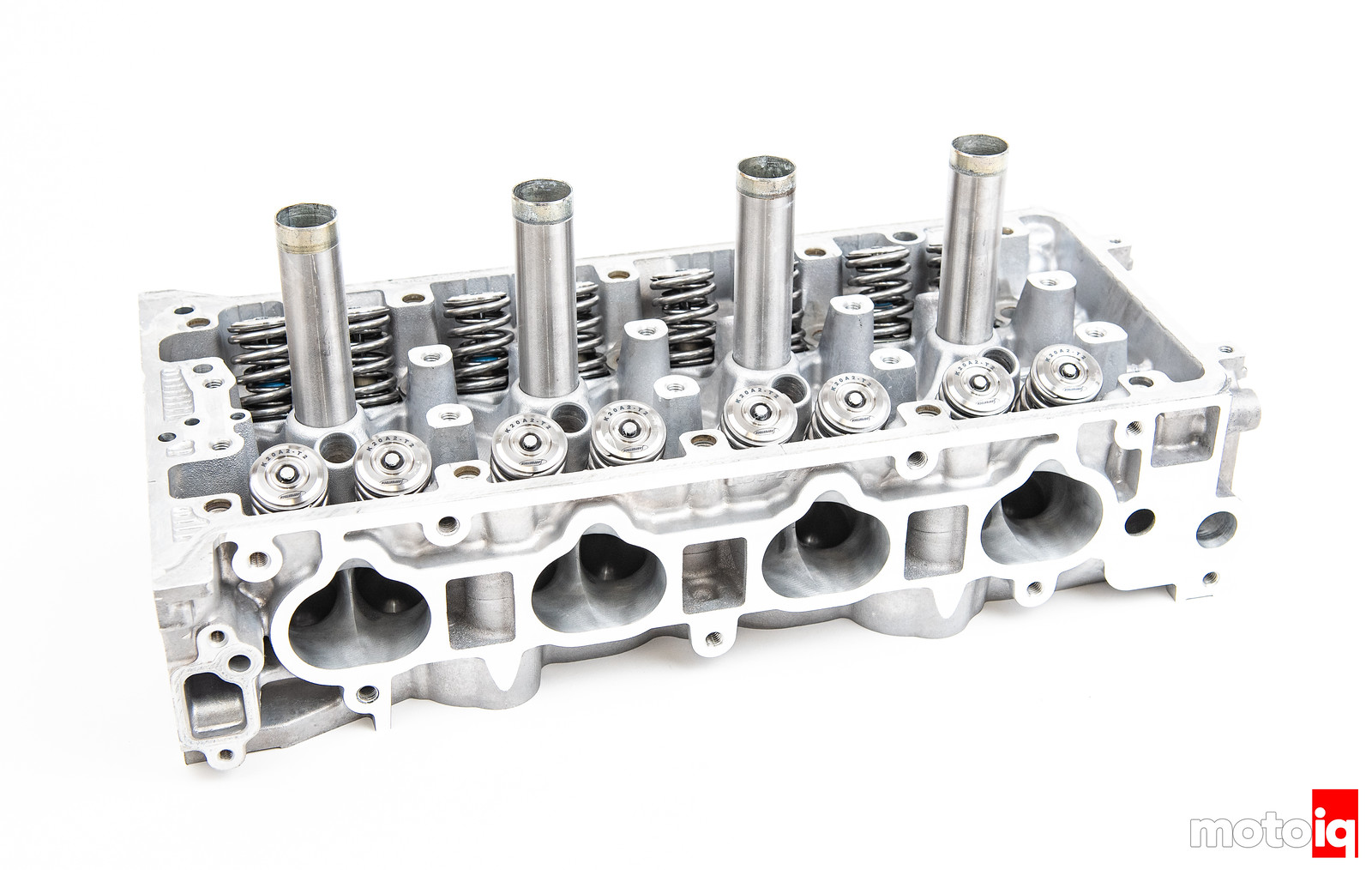

Starting with a core K20A2 head, we stripped it down and sent it to Drag Cartel to work there magic. The first thing that was planned was to replace the stock valves with these high-performance parts from Supertech Performance. The Supertech valves have some features that help them to improve performance and durability in hard use.

The exhaust valve part number HEVN-1020F is made of Inconel 751, an aerospace developed alloy made out of nickel and chromium that is tough, wear-resistant and highly temperature resistant. This is a pretty perfect material for an exhaust valve! The valve is then black nitrided, a surface conversion process that produces a hard, slippery and wear-resistant coating on parts. To aid flow out of the cylinder, the exhaust valve is given a tuliped contour on its back face.

The intake valves part number HIVN-1022F are made out of EV8 stainless steel and also given a black nitride finish. The intake valve back face is flatter to help flow into the cylinder, the opposite of the exhaust valve, think of a nail head. The forward face of the valves is flat to help get higher compression and to have less effect on flame travel in the combustion chamber.

Since we are retaining the operation of the I-VTEC system we opted to keep the stock valve sizes. Larger valve sizes on K engines are known to clash during the operation of the I-VTEC system. For full race applications where the system is disabled, larger valves can be used.

For valve springs we used Supertech performance parts, part number SPRK-H1021D as recommended by Drag Cartel. The springs are made of super clean chrome vanadium alloy. The super clean process prevents contaminates that can cause intergranular stress risers and points where cracks can propagate during cycling. The harmonics of the springs are analyzed and adjusted to minimize the chances of spring surge. The spring stress is also considered during the design of the springs to assure a long cyclic life.

10 comments

I don’t understand why that collector necks down before the V-band, the “reverse cone”. I don’t get how it would not induce a back pulse, granted turbulent flow physics is not my domain.

At what point in a build would you consider going to individual lambda versus the one? Would there be any gain without ITBs?

Okay well I went studying a bit on reverse cones and it seems they do generate a backpulse but in a certain RPM range that backpulse turns into a negative pressure backpulse (because of the megaphone shape) that helps suck in fresh air during valve overlap. The bad side seems to be that it has a negative impact on low RPM torque and leaves a torque dead zone during the transition into that negative pressure backpulse. That dead zone seems to be minimised by 4-2-1 headers since the second pulse mitigates the first one during that transition period… This just confirms that turbulent air is not my domain, I’ll let wizards deal with it.

In my testing, the reverse cone reduces power drop off after the peak as I said in the article.

That would make sense, the pulse sucks air in during valve overlap when your piston is near TDC where it’s not doing anything, so that pulse is virtually lengthening your intake duration.

The article I read was about reverse cone exhausts on MotoGP bikes with high RPM NA 4 where they are used to broaden the usable RPM range.

Good thing ASP only doesn’t do BP headers, I need to spend on a new winter car instead.

I don’t like complications and additional stuff on cars. Maybe for dyno headers, I might do that on a well-funded engine development program. Once you start paying for stuff out of your own pocket, you idea on how you ought to do things changes.

Curious to see how much timing you will be able to run on 91

*their magic

From previous experience with this engine, in the low 20’s.

Wow, that’s it eh? I guess with the cam timing and (maybe) small combustion chamber volume of these engines you do not need to run a significant amount of advance? I have a lot yet to learn on K tuning.

small bore too.

I have a good price on a 2012 SI, but it looks like the Z block is way less popular than the A for tuning, is it just a production quantity thing or is there some downside to the Zs that I don’t know about, I could just drop on a 20A head and keep my stock 11:1 bottom end?

Is anything specially bad on the FG that would need to be addressed for autocross? Like the EP steering/suspension geometry problems?