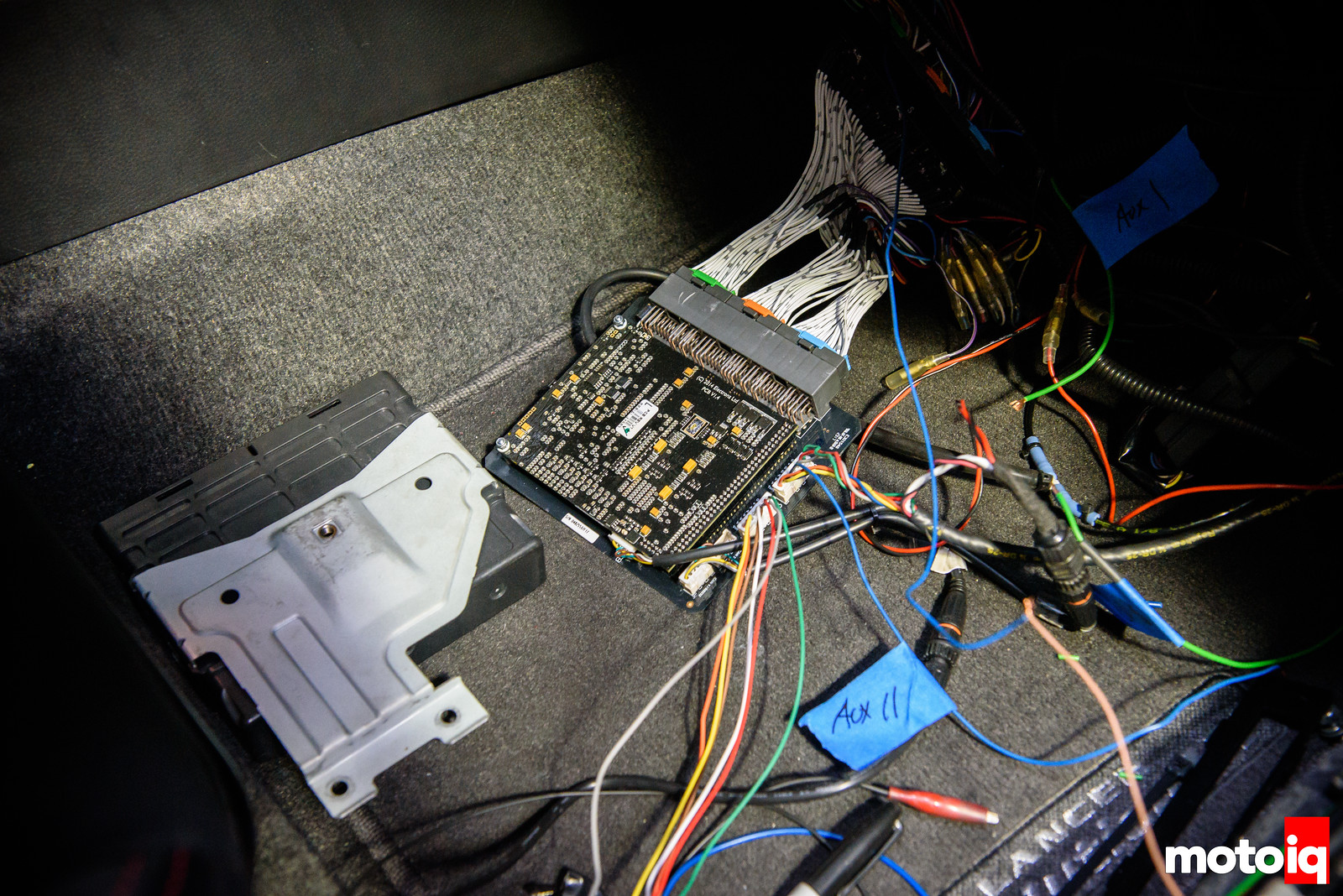

Howard wires in all of our new inputs and outputs according to simple instructions we got from Link.

Jason Oefelein, Link USA’s Vice President, and technical whiz, did a remote check of our system to confirm that our wiring was correct and the Link ECU was seeing everything properly. After a few minor adjustments, all was good. This is another great Link feature and while not unique to only Link is a great help in troubleshooting. While he was doing the remote checking session, Jason also uploaded a base map so we could start the car. The car actually ran decently.

Jason also happens to be on Justin Pawlak’s Formula D team and was in town to work on Justin’s car. He stopped by to give our car a quick tune so we could drive it to the dyno. Here Jason is actually looking at DeatschWerks injector characterization sheet while doing the temporary rough tune.

The next day we met Jason at Dsport Magazine. Dsport has an excellent AWD dyno facility and they were kind enough to let us use it for serious tuning.

Dsport has an AWD Dynojet with a powerful fan system. Good fans are critical for good dyno results. Residual heat and exhaust fumes can affect tuning. Good fans make sure that the engine will see clean fresh air with coolant, air and oil temps simular to actual driving. Jason like many tuners prefers the Dynojet as they feel that the way it loads the motor allows for finer tuning.

The car was strapped down to the dyno rollers and made ready by Dsport’s technicians.

2 comments

Ha ha. An Crydom S.S.R (solid state relay) We use those to turn the heaters on and off on blow molding and injection molding industry.

I designed billet MIVEC housings for the EVO X, it doesn’t surprise me at all that it gets stuck, the whole system works with small springs, edge seals and tiny tolerances balanced with oil pressure. The slightest trace of gunk or grit anywhere will stop it.

The stock casting cracks when you put a bigger turbo in. We fixed the problem in our EVO 9, we removed it and put indexable cam gears instead.