With the car on the dyno, Jason starts tuning, carefully from low loads working his way up to higher loads and rpm filling out the map. I notice that most good tuners are meticulous like this spending a lot of time getting partial throttle and throttle response correct. Tuners that just seem to focus on big numbers and WOT dyno passes frequently seem to produce cars that are sour on the track even though they are big dyno queens.

As he got into the tuning Jason noted that something was wrong with our Mivec variable cam timing system and our idle control valve. It is amazing that these components could die on a car in immaculate shape that has mostly been stored. This is a good statement to show that cars should be periodically driven. Despite these issues, Jason tuned our car around this so we could fix the problems for another tuning session at a later date.

Even with no Mivec, our car produced impressive power and torque figures on 91 octane pump gas. Our car produced 400 whp and 310 lb/ft of torque. This was up from our previous 371 whp even though our torque was down 43 lb/ft from our old 353 lb/ft with working Mivec. Despite having no cam control, our engine had a flat torque curve from 4000 rpm to 8000 rpm and the power was strong to 8000 rpm. Probably this linear torque curve was due to our new Hypertune intake manifold and HKS turbo.

What is really amazing is that this was all done with a lot less boost. Previously we spiked the boost at 27.8 psi at 4500 rpm and tapered the boost pressure down to 22.7 psi at redline. Now we are running a lower 21 psi of boost across the board. With our improvements, we are producing 29 more whp with less boost. Now, this was on a different dyno but it should be decently close as the old power levels were done with a Dynojet correction.

Driving the car was a night and day difference. The car was so amazingly smooth and drivable that the overall driveability, especially slow partial throttle stuff was much better than stock! No more rough running and flat spots. The car felt lively and eager to rev, not like a turbo motor. This is with no Mivec variable cam timing as well. You could really feel the improvement in top-end power with our current state of tune. Even with no idle air control, our idle with the Cosworth M2 cams went from rotary bridge port lumpy to near-stock smooth! Our project Evo IX feels like a whole new car. With Jason tuning the water injection duty cycle, the water injection activation is seamless and you cannot even feel it in action. Before even with careful tuning you could feel a slight flat spot as the water came on but no more. If the water injection system runs out of the water, the ECU will sense the drop in pressure and adjust the map accordingly as well.

We think part of the reason why the car is so driveable is the elimination of the Karman airflow meter, we have always had a feeling that it is not very responsive and sitting at the end of a long intake tract doesn’t help. The intercooler, charge pipe and manifold plenum volume act like an air capacitor and the metering falls behind the actual demand by a bit. This also has an effect on where in the timing map the engine is dwelling at any one moment as well.

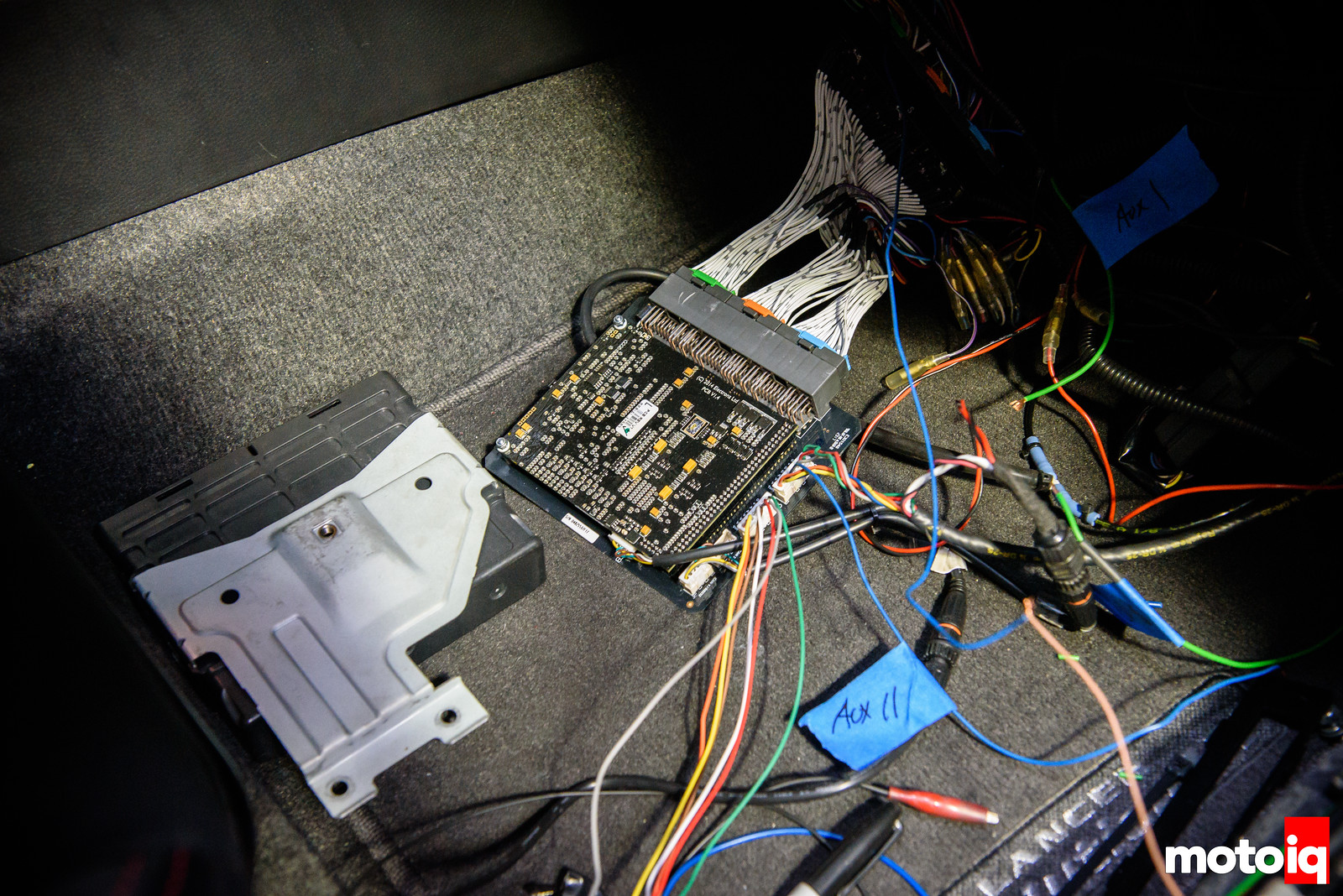

So far we are very impressed with the Link ECU’s ease of install, ease of getting running and ease of capability expansion. Link also has a reputation for being very reliable and guys that know their electronics better than us tell us that the hardware and construction are first-rate. What we also really like is the price and frankly, we are very satisfied with what you get for the money regardless of cost.

So even with these great improvements, it’s back to the drawing board, we will fix the Mivec system and the idle control system and continue to refine our tuning, including tuning for high octane, cool burning E85. Man if we could get our torque back the car will be more than amazing! Even with these systems not working the car was very impressive. Stay Tuned.

2 comments

Ha ha. An Crydom S.S.R (solid state relay) We use those to turn the heaters on and off on blow molding and injection molding industry.

I designed billet MIVEC housings for the EVO X, it doesn’t surprise me at all that it gets stuck, the whole system works with small springs, edge seals and tiny tolerances balanced with oil pressure. The slightest trace of gunk or grit anywhere will stop it.

The stock casting cracks when you put a bigger turbo in. We fixed the problem in our EVO 9, we removed it and put indexable cam gears instead.