The DeatschWerks pump is the exact same configuration as stock and the Walbro pump. What we found amazing is how clogged the pre-filter was in this super clean car that only has 8000 miles on it. Letting cars sit is bad for them, more on that later.

The new filter installs on the new pump just like that.

The new DeatschWerks pump slips right into the stock fuel pump hanger easy peasy.

The pump hanger is put right back into the fuel tank.

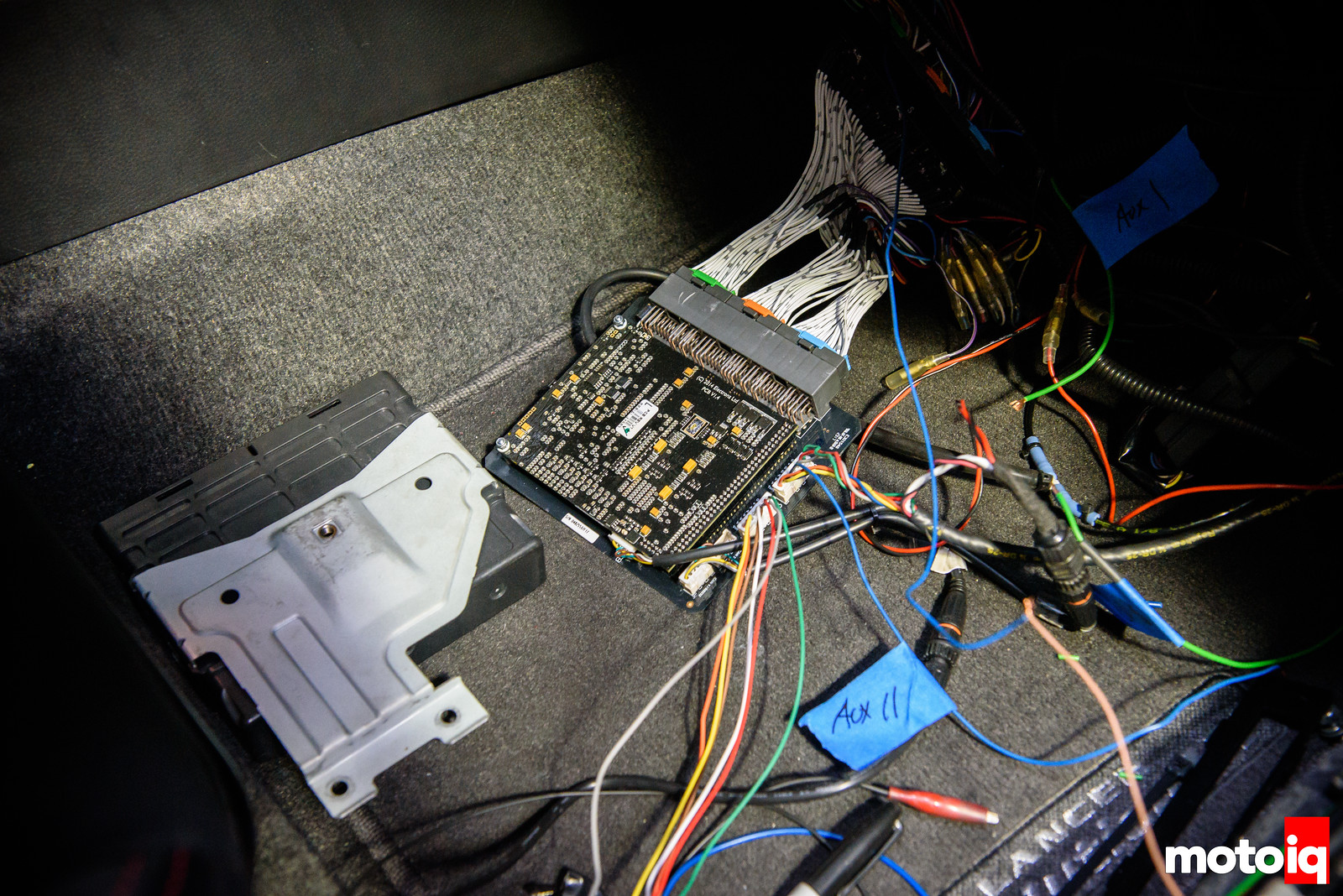

Since we wanted to use the Link Ecu to control our water injection pump via pulse width modulation, we disconnected the AEM pump controller and switched the pump control to the ECU through this Crydom solid-state relay. This is pretty trick and shows off some of the Links capability.

Here is Howard splicing in the Crydom relay. The battery is very close to the water injection pump so it’s also a good place for the relay.

2 comments

Ha ha. An Crydom S.S.R (solid state relay) We use those to turn the heaters on and off on blow molding and injection molding industry.

I designed billet MIVEC housings for the EVO X, it doesn’t surprise me at all that it gets stuck, the whole system works with small springs, edge seals and tiny tolerances balanced with oil pressure. The slightest trace of gunk or grit anywhere will stop it.

The stock casting cracks when you put a bigger turbo in. We fixed the problem in our EVO 9, we removed it and put indexable cam gears instead.