The Link Fuel Ethanol content sensor was mounted to the firewall. The Link ECU actively monitors the ethanol content and adjusts the Fuel, Timing and Boost Maps accordingly. You can run gasoline, ethanol and any combination in between with no effort.

The Link ECU will also monitor the water injection line pressure and boost pressure. It will automatically failsafe if any issues are detected like the pump fails or the system runs out of water.

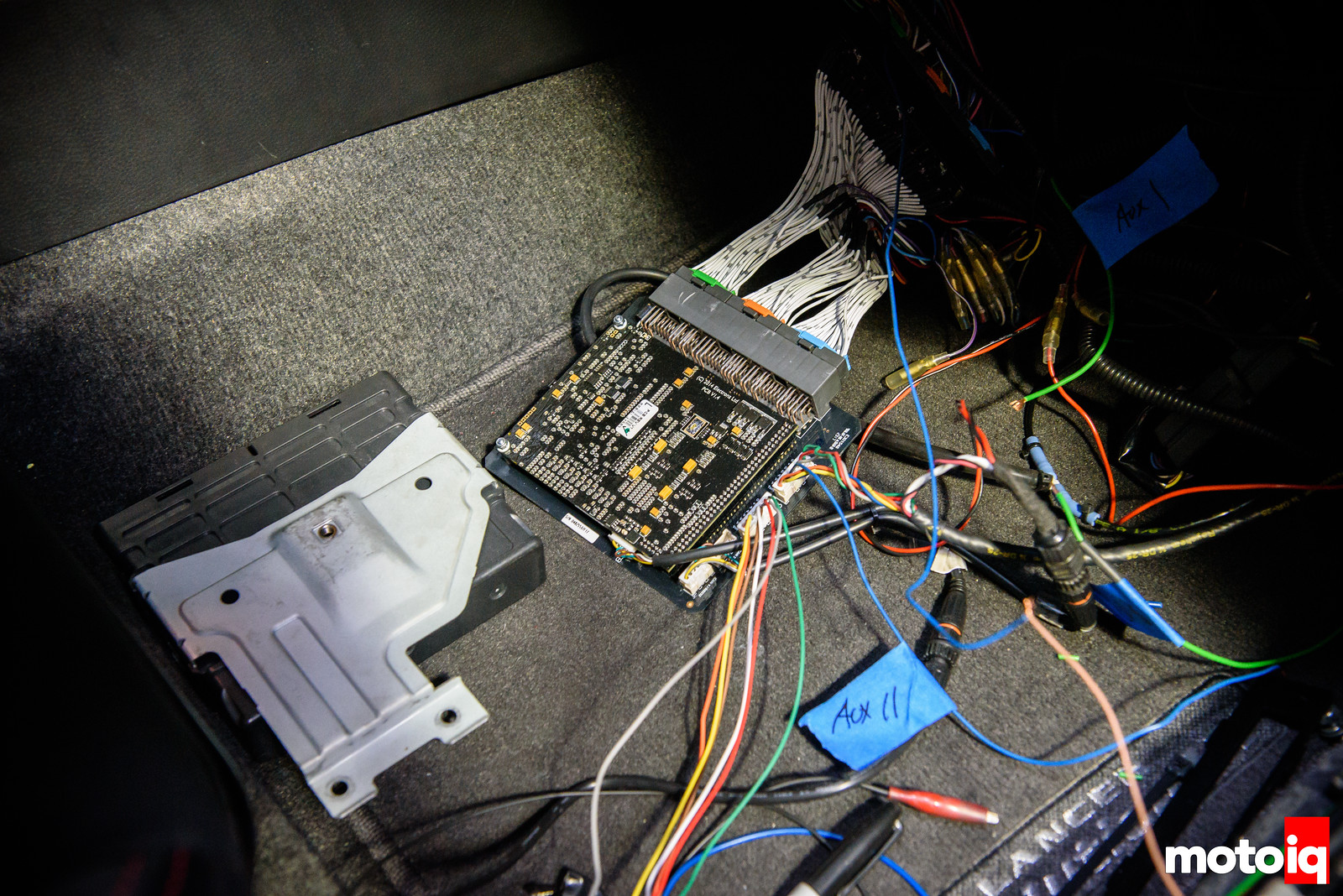

Our Link ECU is a plug and play unit, but we will be using many more of the ECU’s auxiliary inputs for our project. To wire everything neatly, we had Ryan Basseri of Rywire make an auxiliary wire harness for our additional sensors.

Ryan used Raychem wire and shrink tubing to fabricate our new sub-harness. He integrated it into the Link pigtail.

The resulting sub-harness is super clean and the ends are labeled for easy troubleshooting.

Ryan also made adaptor pigtails for the MAP sensor and CAN Lambda sensor.

2 comments

Ha ha. An Crydom S.S.R (solid state relay) We use those to turn the heaters on and off on blow molding and injection molding industry.

I designed billet MIVEC housings for the EVO X, it doesn’t surprise me at all that it gets stuck, the whole system works with small springs, edge seals and tiny tolerances balanced with oil pressure. The slightest trace of gunk or grit anywhere will stop it.

The stock casting cracks when you put a bigger turbo in. We fixed the problem in our EVO 9, we removed it and put indexable cam gears instead.