For our fuel system we will be using Earl’s Twist-On UltraPro hose ends. The UltraPro line of components has been optimized to reduce weight while still providing maximum strength. The dynamic swivel ends combined with the flexibility of the UltraPro hose will make it much easier to plumb our new fuel system around the huge plenum of the new Hypertune intake manifold .

We wanted a leak proof, and good looking, solution for our intake manifold fittings and chose to use Earl’s Auto-Crimp hose ends in their black finish. A few NPT to AN fittings will be used on the car side of things for the AN to hose fittings.

The Earl’s website is a super useful tool for any of your plumbing projects. If you need it, they probably have it! The site is also full of useful product overview and tutorial videos, like this one outlining the process of assembling the UltraPro Twist-On fittings we’ll be using on our project.

An Earls splitter is used so we can feed fuel to both ends of the rail and regulate fuel pressure from the middle of the rail. This is a good touch with systems that flow a lot of fuel like you do when running E85 and the injectors will be fed with shorter runs to avoid starving injectors that are far away from the fuel rail inlet.

To reduce the large throttle body to our charge pipe we used a Vibrant reducer hose coupler.

Since our compressor bypass valve was relocated when Afterhours redid our charge pipe, we used an HPS performance hose with a 90-degree bend to redo the recirculation pipe from the bypass valve to the compressor inlet.

The Earls Ultra Pro adapter fittings with the Auto-Crimp hose ends provide a really clean look for the engine compartment.

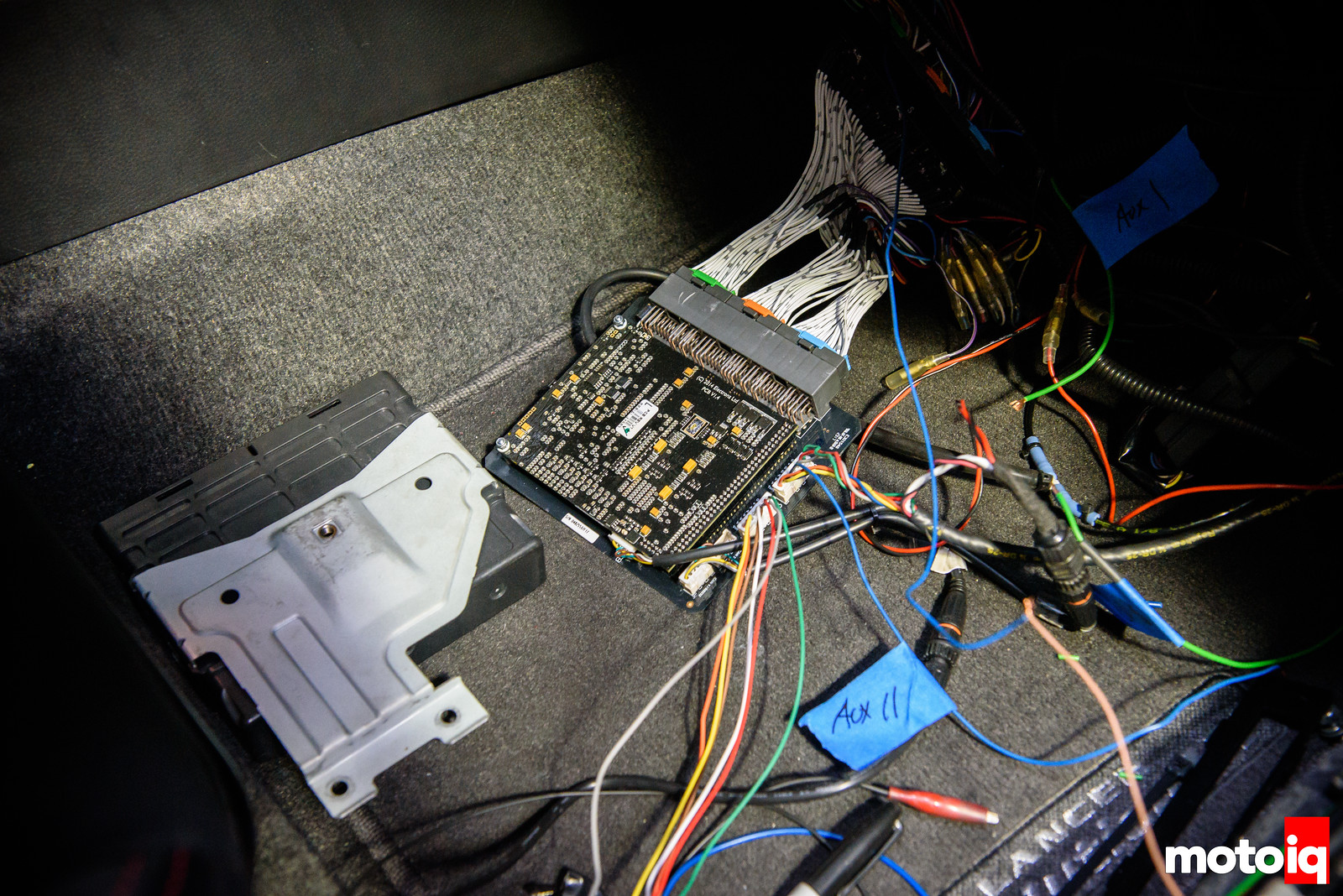

The AEM Electronics high capacity universal fuel pressure regulator will control the fuel pressure on our Evo. It has a wide range of adjustment, a 1:1 boost dependent rising fuel pressure rate, and it’s compatible with E85. The perfect choice for our boosted 4G63, which we will be definitely be turning up the boost on. It also gives us a place to mount the Link fuel pressure sender unit. The Link ECU will actively monitor fuel pressure and will revert to a fail-safe mode should it detects a drop in pressure.

2 comments

Ha ha. An Crydom S.S.R (solid state relay) We use those to turn the heaters on and off on blow molding and injection molding industry.

I designed billet MIVEC housings for the EVO X, it doesn’t surprise me at all that it gets stuck, the whole system works with small springs, edge seals and tiny tolerances balanced with oil pressure. The slightest trace of gunk or grit anywhere will stop it.

The stock casting cracks when you put a bigger turbo in. We fixed the problem in our EVO 9, we removed it and put indexable cam gears instead.