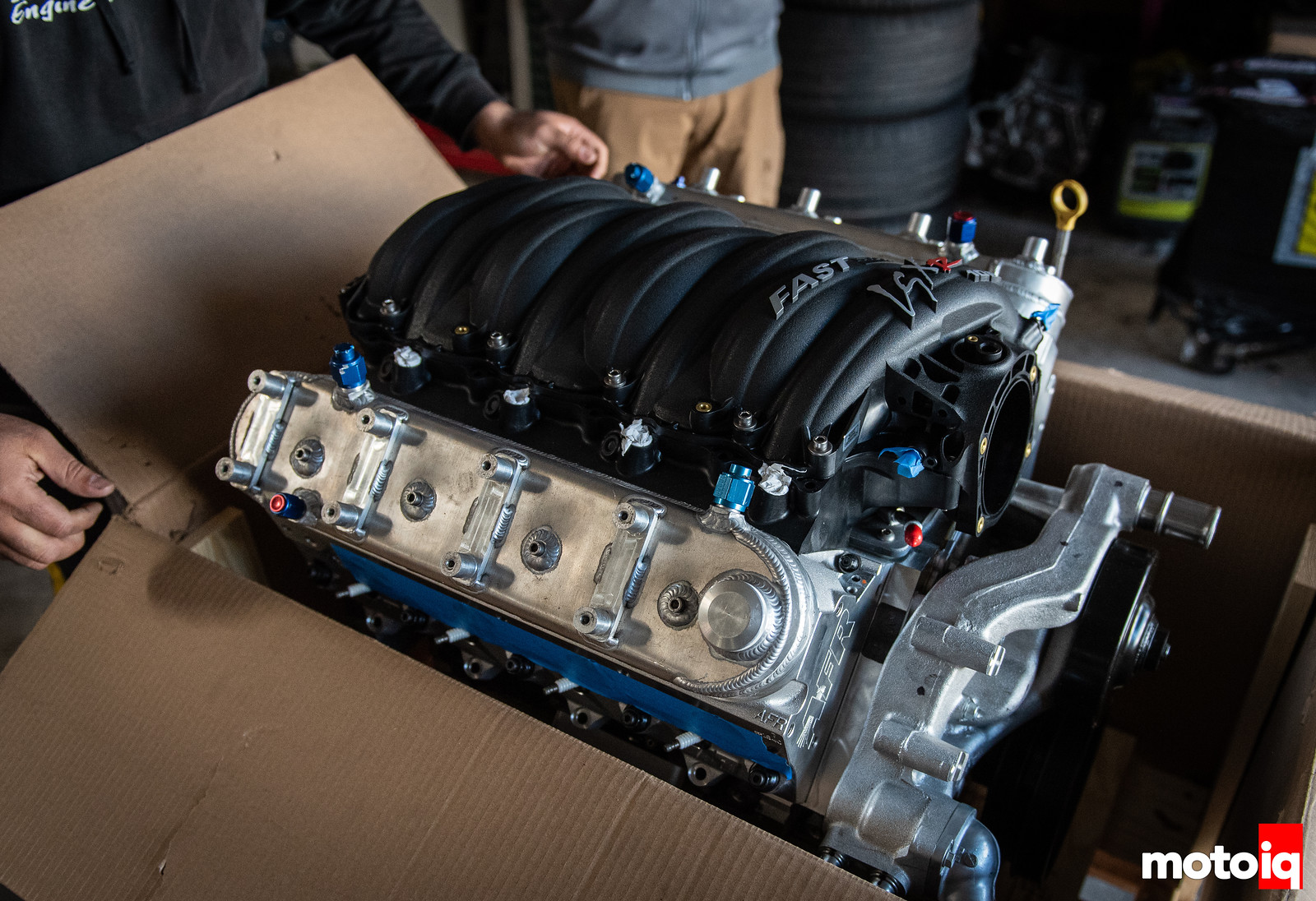

In the first installment of our drift spec LS3 build, we discussed our parts selection and listed the part numbers for building a 650 whp NA monster with parts from Comp Cams, FAST, JE and Eagle among others. Now in this segment, we will be assembling our LS so check it out! We also shot a video discussing some of what went into the build as well if you would like to view it.

Our nice fresh LS3 block straight from the machine shop. Since we are using studs with higher torque, we send our blocks, even new ones out to have them aligned bored and honed. This is because the greater torque causes additional distortion to the top of the bores. We hard hardly taking any material out, just truing things up. Another thing to consider is that stronger studs don’t yield and the aluminum block grows 2x faster than them with heat so the clamping force and bore distortion increase with heat. Thus making sure the bores are round with torque really helps leakdown, friction, engine life, and power.

We use a fine diamond hone and plateau hone with a cork bonded hone to assure low friction, quick break-in, and excellent ring seal. You can really feel the difference plateau honing makes with your hand. Plateau honing cleanly knocks the sharp peaks off of the honed crosshatch pattern without folding them over.

Our King Bearings and ARP studs are installed next. We apply some assembly lube to the bearings to make sure they have lubrication when the engine first starts before the oil pressure comes up.

The bearings are applied to the main caps as well and covered in assembly lube. When selecting the bearings for proper clearance, we have found on the aluminum block LS motors that you should set your clearances to the tight side of the factory recommended specs. The aluminum block really expands when it heats up and the clearances increase and the hot oil pressures drop. When using a wet-sump, even with a high volume pump, the oil pressure might be as low as 45 psi at high rpm which is ok but we like to see a little more than that in a hard use engine.

11 comments

Want to purchase 2010 SS Camaro Automatic

Would the motor in this vehicle be rebuilt to the specs in this video or would you place a new motor of your specs into the vehicle?

VIN 2G1FK1EJ7A9207576

Car is listed local to you on Carvana

We would teardown and inspect the engine to make sure it would be suitable for a rebuild.

Can you tell us what the cam specs are?

256 degrees of duration at 0.050″ lift on the intake and 273 degrees duration on the exhaust. The lift is 0.712″ on the intake and 0.688″ on the exhaust side. The lobe centers are 107 degrees on the intake and 115 degrees on the exhaust with a 111-degree lobe separation angle

Do yall offer engine building services i collapsed a lifter in my engine and an fixing to just go ahead and rebuild it to these specs.

Yes but this engine isn’t cheap.

Is it possible to get a complete parts list for this build?

What is the cost to build 650hp LS3

something like 16 to 22k depending on if you supply a useable core engine or not.

For a hydraulic lifter engine similar to this. Used in circuit racing, what would you recommend for cam size , lift etc. LSA ?? It will be a 4.010 bore 4 inch stroker

I don’t recommend hydraulic lifters for racing.