The cylinder heads are put into place.

The ARP nuts are run down then torqued in steps in a cross pattern. Like every other critical bolt and nut, it is important to burnish in the threads, washers, and seats as well as to use the correct ARP lubricant to get good torque readings.

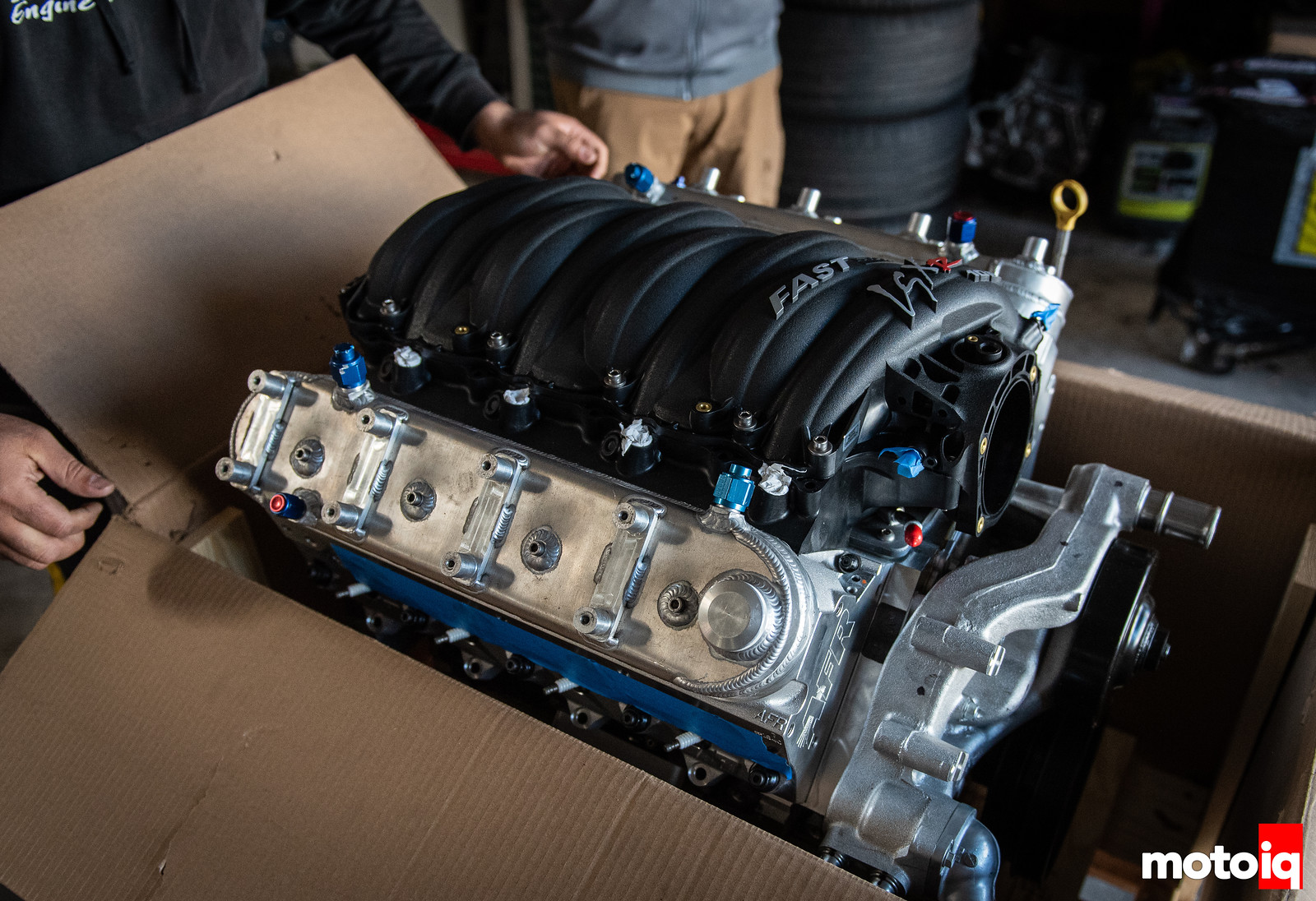

Our pile of parts is starting to look like an engine!

We do a quick double-check to make sure our shaft stand shimming is correct for the lift our cam has.

Now our Crower shaft rockers and Engine Pro pushrods are installed and the valve lash is set. That is some trick hardware and should prove to be quite reliable.

Our Mellings high volume and pressure oil pump is now installed on the nose of the crank.

11 comments

Want to purchase 2010 SS Camaro Automatic

Would the motor in this vehicle be rebuilt to the specs in this video or would you place a new motor of your specs into the vehicle?

VIN 2G1FK1EJ7A9207576

Car is listed local to you on Carvana

We would teardown and inspect the engine to make sure it would be suitable for a rebuild.

Can you tell us what the cam specs are?

256 degrees of duration at 0.050″ lift on the intake and 273 degrees duration on the exhaust. The lift is 0.712″ on the intake and 0.688″ on the exhaust side. The lobe centers are 107 degrees on the intake and 115 degrees on the exhaust with a 111-degree lobe separation angle

Do yall offer engine building services i collapsed a lifter in my engine and an fixing to just go ahead and rebuild it to these specs.

Yes but this engine isn’t cheap.

Is it possible to get a complete parts list for this build?

What is the cost to build 650hp LS3

something like 16 to 22k depending on if you supply a useable core engine or not.

For a hydraulic lifter engine similar to this. Used in circuit racing, what would you recommend for cam size , lift etc. LSA ?? It will be a 4.010 bore 4 inch stroker

I don’t recommend hydraulic lifters for racing.